Custom injection mold & plastic injection molding Manufacturer

We provide turnkey serviceS from mold design, mold making, plastic injection molding to 24/7 customer service.

–-Our mold designers with at least 10 years’ industry experience.

–They check the shrinkage rate, sizes and geometry of the injection molded parts.

–Rich experience in complex parting surface design.

–Molds meet EN 12472 standard.

–DFM(Design for Manufacturability) and mold flow analysis are employed.

–CAD/CAM/CAE capabilities

–Cost Reduction Suggestions without compromising quality.

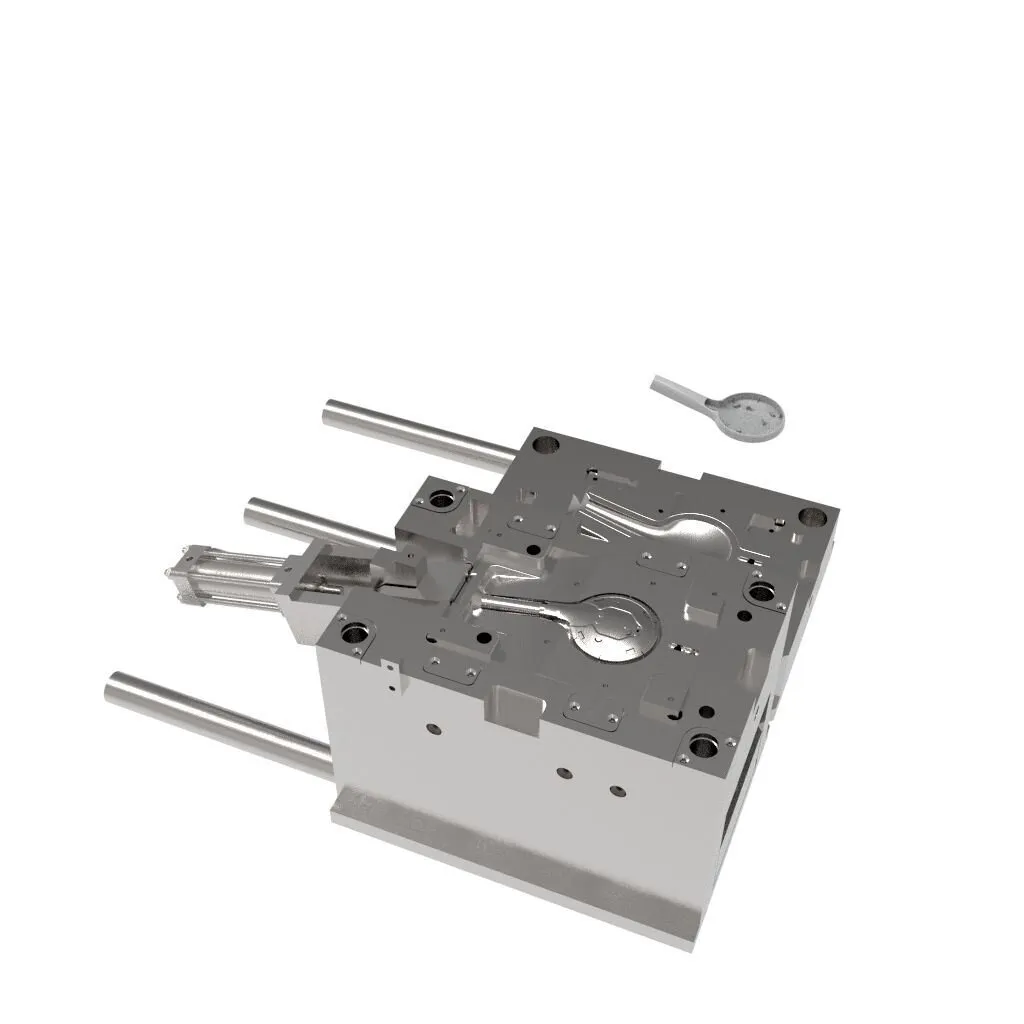

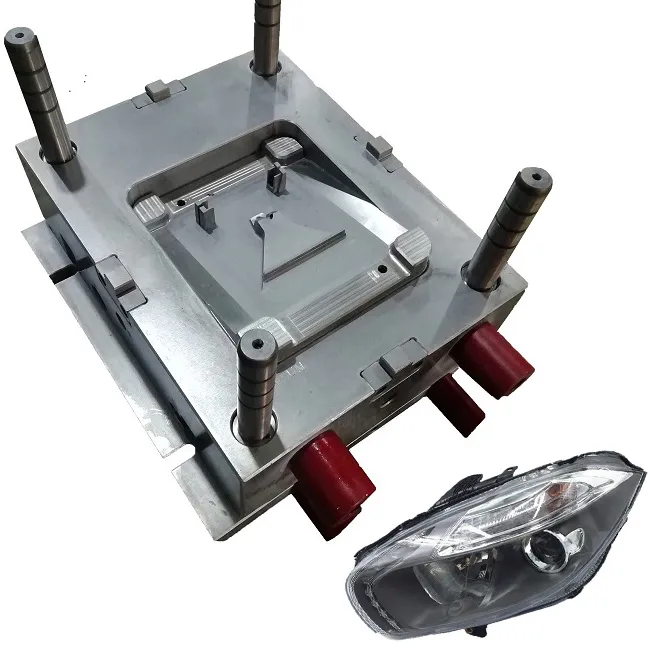

Mold Making

–Most advanced CNC and EDM including 5-axis ,slow-speed wire and mirror EDMs to ensure high precision and gloss

–Rich experience in big size mold tooling.

–Our molds can be traceable.

–Max.mold life:> 1 million cycles;

–Precision:<+/-0.01mm

–No M.O.Q. and 7-30 days lead time.

–Rigid quality inspection system including IQC,IPQC,FQC,OQC and NCR. Coordinate Measuring Machine report is available.

–Multi-cavity and world famous brand hot runner systems are available

–Comply with ISO9001, IATF 16949 and ISO13485.

Injection Molding

–Comply with ISO9001, IATF 16949 and ISO13485.

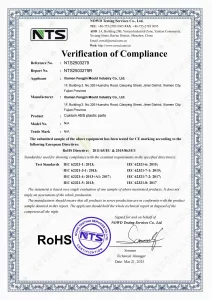

–Plastic materials are RoHS certified.

— Handle a wide range of plastic materials.

–Serve different industries especially

sanitary wares, sports,home appliance,

electronics and automotive.

some Custom injection molds

Shower head Injection Mold

Automobile Mirror mold

Multi-cavity connector Mold

Medical Cover injection mold

Some plastic injection molded parts

Two- Function waterway

Toilet seat&cover

Shower Head Set

Golf Tees

Tennis Frame

Blue tooth headphone cover

Protection Cover

Portable Printer Housing

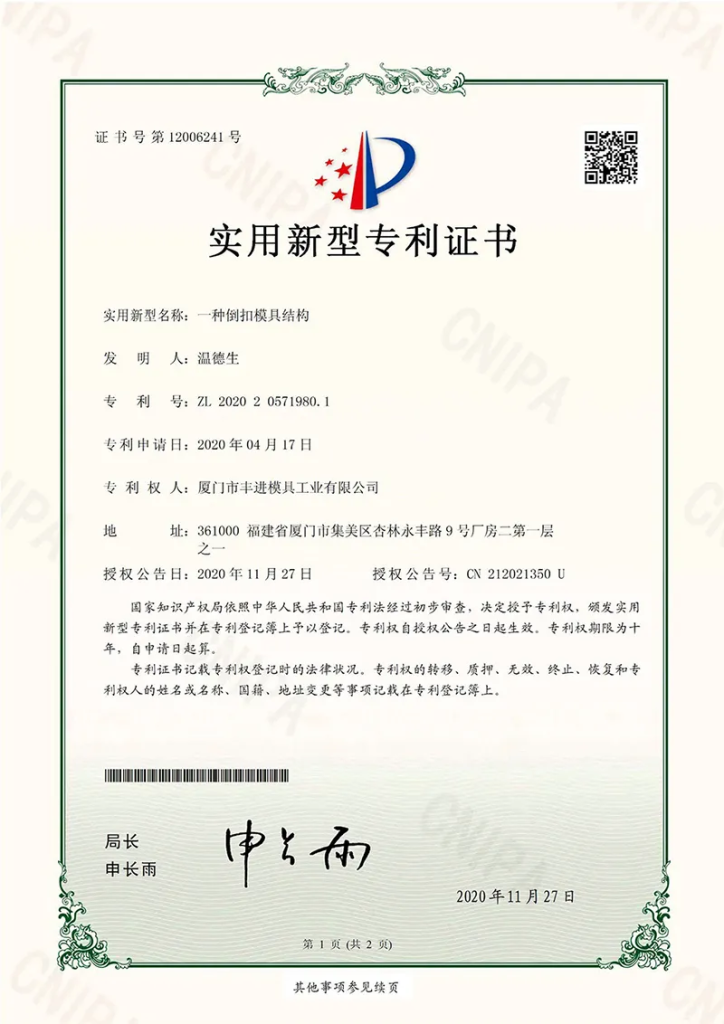

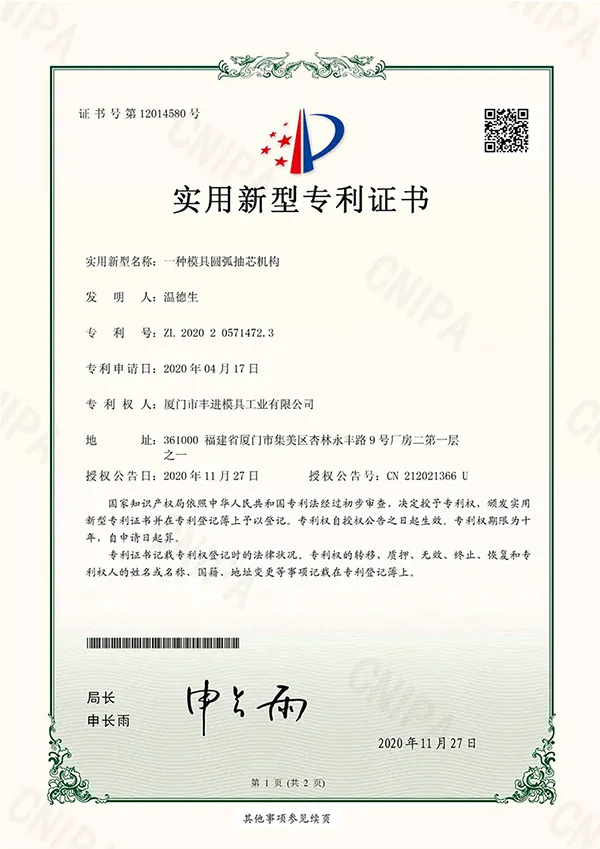

Some certificates

ISO9001:2015

plastic Injection Mold Patent

plastic Injection Mold patent

RoHS certificate

Some ClientsEASO : Top Manufacturer Of Shower Products. TOTO/KOHLER/RUNNER: Top Manufacturers Of Sanitary Wares KEENTECH/WILSON: Top Manufacturers Of Tennis Rackets. OGAWA: Top Manufacturer Of Massage Armchairs.

Injection Molding Finish

| Materials | Color | Description | |

|---|---|---|---|

| Smooth | ABS PC PE PP PMMA PS | ALL colors | Polish the mold cavity to #1200 sand paper to make parts surface smooth. |

| Painting | ABS PC PE PMMA PS | All colors | Spray a layer of paints on the surface of the products to protect them and make them look better. |

| Silk Screen | Most common plastic | All colors | Print the logo, words or patterns on the surface of the products by silk screen. |

| Plating | ABS, PC | All colors | Electronical plating makes the product look shining. The shining layer is chrome. |

Injection Molding VS Rapid Prototyping

Injection molding is used for large quantity production while rapid prototyping for low volume production.

- Injection molding offers low unit price but high cost injection mold, rapid prototyping makes parts without mold.

- Injection molding produces thousands of products in several days, more efficient than rapid prototyping.

- We start injection molding after confirmation of final products and rapid prototyping at the stage of product design and development.

- The strength of injection molded parts are higher than prototypes.

- There will be gate residue, pin mark, parting line on the injection molded parts, and prototypes don’t have these.