An Improved demolding Structure for an inverted Injection Molded part

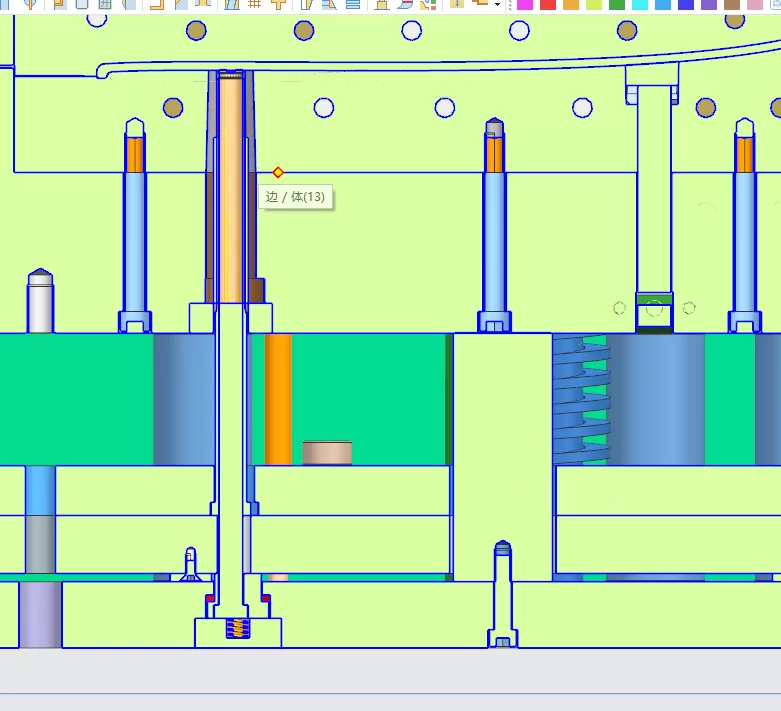

To force demolding of this injection molded part with an undercut, directly forcing demolding would damage the plastic part. Instead, this side is modified with an ejector sleeve structure. The ejector sleeve pushes out first, causing the undercut ejector pin to exit the cavity. The ejector sleeve then continues to push out, creating space for the injection molded component to expand and force demolding. During the injection mold closing, the ejector plate presses the core back onto the base plate, causing the ejector sleeve pin to reset. For more information, please contact us at sales6@xmfengjin.com